- Description

-

Product Details

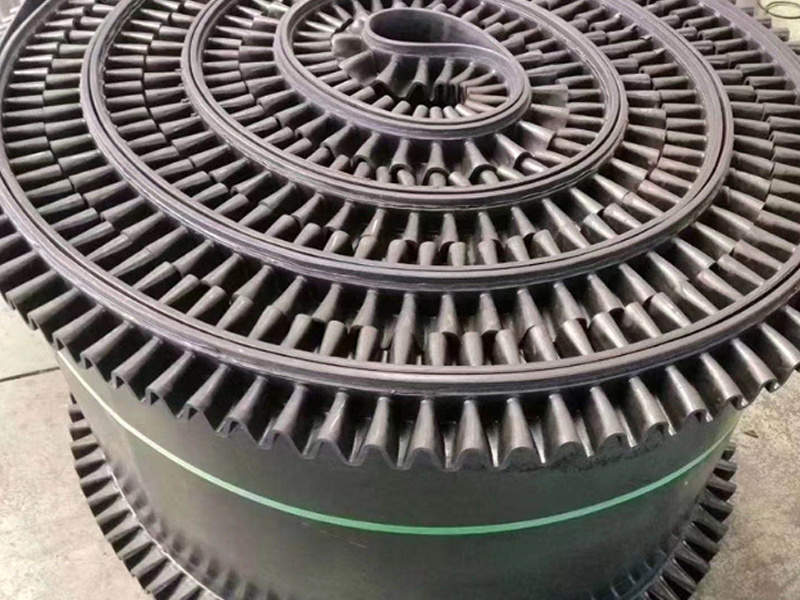

Fabric (NN/EP) conveyor belt, the middle sandwich canvas is nylon canvas. The fabric (NN/EP) conveyor belt has the characteristics of thin belt, high strength, impact resistance, good grooving, large interlayer adhesion, excellent flexibility and long service life. It is suitable for conveying materials under medium and long distance, high load and high speed conditions, and is widely used in mines, coal yards, chemical industry, metallurgy, construction, ports and other departments. Fabric (NN/EP) conveyor belt Compared with ordinary cotton core conveyor belt, fabric (NN/EP) conveyor belt has the advantages of high strength, impact resistance, high elasticity, good groove forming and light weight. Fabric (NN/EP) conveyor belts can reduce material transportation costs and help companies achieve high-speed material transportation over large spans and long distances.

Nylon is one of the varieties with better performance in all synthetic fibers in the rubber industry at present. Its structure warp and weft direction is a variety with a wide range of weaving applications of nylon fibers. Its most prominent advantages are good wear resistance, high strength and fatigue resistance. The conveyor belt made of nylon canvas has the characteristics of thin belt body, high strength, impact resistance, good grooving, large interlayer adhesion, excellent flexibility and long service life, etc. It is suitable for medium and long distance, high load, high-speed transport of materials, widely used in mining, metallurgy, construction, ports and other departments.

Standard Name Type Standard number and update time Tensile strength MPa ≥ Elongation at break% ≥ Abrasion mm3 ≤ Hardness Shore A Aging test Standard number and type Formula number used by Huaxia Aging condition/change rate of tensile strength% Aging test Tensile strength change Change rate of elongation at break% Ozone aging test Japanese Standard-Steel Cord Conveyor Belt JISK 6369-S 18.0 450 200 70℃x168h±25 70℃x168h±25 No ghost crack JISK 6369-A 14.0 400 150 JIS K 6369-L P15、XP 15.0 350 200 No regulation JISK 6369-D M18、XP 18.0 400 100 JIS K 6369-H P25/P25 head glue, XP 24.0 450 120 Japanese Standard-Fabric Core Conveyor Belt JIS K 6322-P P12、T1-3 8.0 300 400 70℃x168h±40 70℃x168h±40 No regulation JISK 6322-G P14、T1-3 14.0 400 250 70'℃x168h±30 70℃Cx168h±30 JIS K 6322-S 18.0 450 200 70℃x168h±25 70℃x168h±25 No ghost crack JIS K 6322-A 14.0 400 150 South African Standard-General Purpose Fabric Core Conveyor Belt SANS 1173-A M20、T1-3 18.0 400 70 70℃x168h±20 70℃x168h±20 SANS 1173-C M20、T1-3 20.0 400 150 SANS 1173-M P25/P25 head adhesive, T1-3 25.0 450 120 SANS 1173-N PM17、T1-3 17.0 400 150 South African Standard-Steel Cord Conveyor Belt SANS 1366-F P14、XP 14.0 400 180 70℃x168h±20 70℃x168h±20 SANS 1366-A M20、XP 18.0 400 70 SANS 1366-C M20、XP 20.0 400 150 SANS 1366-N PM17、XP 17.0 400 150 SANS 1366-M P25/P25 head glue, XP 25.0 450 120 American Rubber Manufacturers Association Standard RMA-I PM17、T1-3 17.0 400 120 RMA -II P14、T1-3 14.0 350 150 Fabric Type Fabric construction Fabric type Thickness of adhesive tape Strength series (N/mm) Cover glue thickness Width range Belt length By Weft Layer 2 Layer 3 4 floors 5 floors 6 layers Upper cover glue Lower cover glue Nylon nylon nylon Nn-100 0.75 210 310 410 510 610 1.5-8 0-4.5 410-2550 ≤ 310 Nn.125 0.80 240 365 510 620 740 NN150 0.90 280 430 610 740 920 Nn-200 0.95 300 580 810 1050 1250 NN250 1.00 350 730 1050 1200 1550 Nn-300 1.10 450 890 1250 1450 1850 510-2550 EP-350 1.25 - 1100 1450 1700 2050 EP-400 1.60 - - 1650 2000 2380 EP-500 1.70 - - 2050 2400 3100 810-2550 German Standard DIN-22102 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesion strength between cover layer and cloth layer (/mm) Covering layer thickness 0.8~1.5mm Cover layer thickness> 1.5mm W 18 400 90 ≥ 5 3.5 4.5 X 25 450 120 Y 20 400 150 Z 15 350 250 English Standard BS 490 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesion strength between cover layer and cloth layer (/mm) Covering layer thickness 0.8~1.5mm Cover layer thickness> 1.5mm M 24 450 - ≥ 5.25 3.15 4.5 N 17 400 - Australian Standard AS 1332-2000 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesion strength between cover layer and cloth layer (/mm) Covering layer thickness 0.8~1.5mm Cover layer thickness> 1.5mm A 17 400 70 6 4 4.8 E 14 300 - F 14 300 - M 24 450 125 N 17 400 200 S 14 300 250 S* 12 300 250 South Africa SANS 1173:2005 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesive strength between cover layer and cloth layer (N/mm) A 18 400 90 ≥ 7 ≥ 5 X 25 450 120 M 24 450 150 N 20 400 250 Specification and Technical Parameters of Nylon Multilayer Fabric Core Conveyor Belt

Fabric Type Fabric construction Fabric type Thickness of adhesive tape (mm/p) Strength series (N/mm) Cover glue thickness Width range (mm) By Weft Layer 2 Layer 3 4 floors 5 floors 6 layers Upper covering layer Lower cover Nylon cotton nylon cotton nylon Nn-100 1.00 200 300 400 500 600 0-12 0-10 400-4000 Nn-125 1.05 250 375 500 625 750 Nn-150 1.10 300 450 600 750 900 Nn-200 1.20 400 600 800 1000 1200 Nn-250 1.40 500 750 1000 1250 1500 Nn-300 1.50 600 900 1200 1500 1800 NN-500 1.60 1000 1500 2000 2500 3000 Adhesive strength, elongation performance in accordance with the following table

Adhesion strength, elongation performance Core material bond strength Extension performance Interlayer N/mm Covering layer and layer N/mm Full thickness longitudinal elongation at break Full thickness longitudinal reference force elongation Covering layer thickness ≤ 1.5mm Covering layer thickness ≥ 1.5mm Polyester Canvas ≥ 5 ≥ 4.5 ≥ 5 ≥ 10% ≤ 4% 6 The covering performance of the tape is in accordance with the following table

Covering performance of tape Overlay Level Tensile strength Elongation at break Abrasion Change rate of tensile strength and elongation at break after aging Mpa Kgf/cm2 % mm3 % H ≥ 24 ≥ 240 ≥ 450 ≤ 120 -25~ 25 D ≥ 18 180 ≥ 400 ≤100 -25~ 25 L ≥ 15 150 ≥ 350 ≤200 -25~ 25

Advantage

In the production management, high, fine, strict word check. In the selection of raw materials, the first choice of national excellent enterprises and products, all raw materials into the factory must be inspected, qualified before they can be put into production. The inspection policy implemented by our company is self-inspection, mutual inspection, special inspection, layer upon layer to control the quality inspection, so that the product quality is always in a controlled state in the manufacturing process.

Factory Direct Sales

Selected Raw Material

Processing Customization

Durable

Intimate After-Sales

Timely Delivery

Company Profile

Baoding Lixin Tape Manufacturing Co., LTD., located in Li County Rubber Industrial Park, Baoding City, Hebei Province, is a modern enterprise focusing on the development, production and sales of conveyor belts. The company was founded in 1995, after years of development, now has the domestic advanced level of production line, become a leader in the conveyor belt industry.

The company attaches great importance to the construction of quality management system, and the management mode has passed the ISO 9001 international quality system certification and 2000 standard certification. Through the strict quality control process, from raw material procurement to product delivery, every link is strictly tested to ensure that product quality meets international standards.

Customized Delivery Process

The company attaches great importance to the construction of quality management system, and the management mode has passed the ISO 9001 international quality system certification and 2000 standard certification. Through the strict quality control process, from raw material procurement to product delivery, every link is strictly tested to ensure that product quality meets international standards.

Goods will be strictly tested before delivery, please check carefully after receiving the goods, if there is any problem, please contact us in time.

Online Communication

Provide Custom Drawings

Merchant Quotation

Sign A Contract

Processing And Production

Packaging And Distribution

Confirm Receipt Of Goods

Successful Transaction

Previous:

Next:

Nylon conveyor belt

If you need customized products, Contact US !

Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.